| Air Pressure Regulator Cum Filter for Spray Atomization |

Janatics Make suitable for 0 to 10 kg/cm2 |

| Air Inlet Temp |

Ambient to 250° C; Accuracy ± 10 C In steps of 0.10 C through PLC. |

| Outlet Temp |

30°C to 120°C, Accuracy ± 10 C In steps of 0.10 C through PLC. |

| Power Temp |

30°C to 90°C, Accuracy ± 10 C In steps of 0.10 C through PLC. |

| Built in hot plate with Magnetic Stirrer. |

Capacity – 1 lit hot plate with Magnetic Stirrer controlled through PLC in steps of 1% accuracy + 1% |

| Materials of Construction |

|

| Main Body (Stand) |

SS 316 – with dull GMP pharmaceutical external finish by glass bead shot blasting Acid Resistant– Internally buffed to M-I dead mirror finish. |

| Air Heater Body (Flame proof heaters) |

SS 316 |

| Air Heater Element |

Incolloy 800 |

| Air Distributor |

SS 316 |

| Spray Nozzle |

SS 316L size 0.7 mm two fluid co-current with auto deblocking device. Nozzle having 250 microns teflon coating externally with 0.5, 0.7, 0.8 /1.0 /1.2 mm orifice tips |

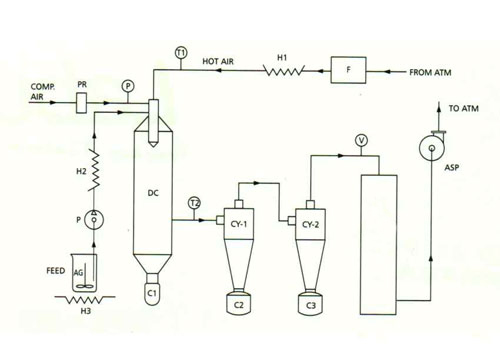

| Drying Chamber |

MOC SS 316 with insulation jacket with sight & light glass. |

| Cyclone |

MOC SS 316 |

| Product Receivers |

Threaded borosilicate glass with threaded Teflon cover. |

| Collection bottle |

Borosilicate glass; annealed- stress relieved – spark tested |

| Scrubber |

SS 316 , having top Teflon cover, fitted with single PP / antistatic nylon filter bag having porosity 3 microns |

| Connecting Tubing |

SS 316 piping |

| Cover of Product Receivers |

Pure Teflon |

| Tube for Peristaltic Pump |

Pharmed Silicon Tubing |

| Hepa Filter for gasses to be recirculated in closed loop |

Hepa Filter – 0.3 microns |

| All Sealing gaskets & ‘O’ Rings |

Teflon/ Pure silicon |

| Built In Control System |

| PLC based system with RS 485 port with Alphanumeric / Graphic LCD display & annunciation Panel with audio visual indications with two way communication between Touch screen & computer configuration. |

| All the devices, functions, settings, process data provided with Windows XP compatible software with online data logging of all variable parameters and trends of inlet temp. / outlet temp./product temp. and oxygen % when connected with inert loop. |

Facility for storage of all data logging / trends on PC configuration.

- • The PLC circuit will with 24V power supply for Input interrogation & for powering DC Relays.

- • ELCB protection is provided for - 2 Pole ELCB for Mains Incoming 220V- Single Phase Supply, 2 Pole MCB for Elect. Heater, 2 Pole MCB for Hot Plate.

- • Control Panel is provided with 1 no. Isolation relay

- • SSR is provided for 3.0 KW Elect. Heater.

- • 4 nos. Temperature Sensors (PT 100) are provided for inlet/outlet / Hot plate & heater safety cut-off temperature.

|

| Power Supply |

Single Phase 220V, 50HZ. |

| Max Current Drawn / Power Consumption |

12 Amps max |

| Overall Dimensions |

Complete Unit - 1500mm x 1500mm x 500mm (H x W x D) |

| Weight of the System |

150kg |